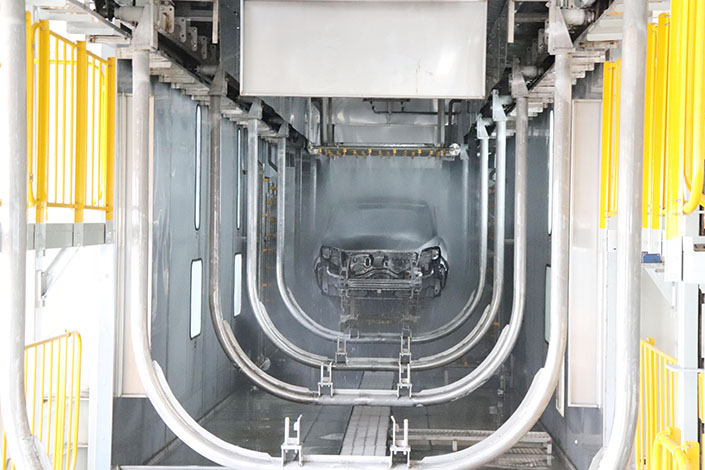

buufin nooca pretreatment line wax soo saarka

Dahaarka ka hor daawaynta waxaa ka mid ah hoos u dhigista (degreasing), ka saarida miridhku, fosfitinta saddex qaybood.Phosphating waa isku xirka dhexe, hoos u dhigista iyo ka saarista miridhku waa habka diyaarinta ka hor fosfatinta, sidaas darteed dhaqanka wax soo saarka, waa in aan kaliya qaadan shaqada fosfatinta sida diiradda, laakiin sidoo kale ka bilow shuruudaha tayada fosfooraska, samee shaqo wanaagsan marka lagu daro saliidda iyo miridhku ka saarista, gaar ahaan fiiro gaar ah u leh saamaynta wadaagga ah ee ka dhexeeya.

Duur-u-yeelista

Iyadoo horumarinta warshadaha, ilaalinta deegaanka iyo hagaajinta xaaladaha shaqada waxay noqdeen welwelka guud ee dadka.Sidaa darteed, baahida ilaalinta deegaanka waa in la tixgeliyaa marka la dooranayo wakiilada.Sidaa darteed, doorashada wakiilka saarista saliidda waxay u baahan tahay diyaarin fudud, awoodda deconfouling waa mid xooggan, kuma jiraan sodium hydroxide, silicate, OP emulsifier iyo qaybaha kale ee adag in lagu nadiifiyo heerkulka qolka, si sahlan loo dhaqo heerkulka qolka, kuma jiraan sunta. walxaha, ha soo saarin gaasaska waxyeellada leh, xaalado shaqo oo wanaagsan.Xulashada ka saarista miridhku waxay u baahan tahay in lagu daro dhiirrigeliyeyaasha, xannibaadayaasha daxalka iyo horjoogayaasha, waxay hagaajin karaan xawaaraha ka saarista miridhku, waxay ka hortagaan workpiece-ka-daxalka iyo embrittlement hydrogen, waxay si fiican u joojin kartaa ceeryaamo acid.Miyuu si gaar ah istaahilaa ceeryaamo acid inhibiting, dhacaya habka of pickling ceeryaamo acid, daxalka qalabka iyo dhirta, ma aha oo kaliya nijaasayn deegaanka, oo waxay keeni kartaa suus ilkaha, casaan conjunctival ilkaha, ilmada, xanuun, cunaha qalalan, qufac iyo calaamado kale. , si wax ku ool ah u joojiso ceeryaamo acid, ma aha oo kaliya baahida ilaalinta deegaanka, ama caafimaadka aawadood ee baahida shaqaalaha.

Biyo dhaqid

Dhaqidda ka dib saarista saliidda iyo ka saarista miridhku, inkasta oo ay iska leedahay habka kaaliyaha ka hor rinjiyeynta, waxay sidoo kale u baahan tahay inay keento fiiro gaar ah.Ka dib ka saarista saliidda iyo ka saarista miridhku, dusha sare ee workpiece waa sahlan tahay in ay u hoggaansamaan qaar ka mid ah surfactants non-ion iyo CL-.Haddii walxahan haraaga ah aan si fiican loo nadiifin, waxay keeni karaan khafiifinta filimka fosfatka, cilladaha tooska ah, iyo xitaa fosfitinta.Sidaa darteed, si loo hagaajiyo tayada biyaha lagu dhaqo ka dib marka laga saaro saliidda iyo ka saarista miridhku, waxaa lagama maarmaan ah in la maro biyo raacis badan, laba biyo raacis, waqti 1-2min, oo si joogta ah u beddelo biyaha si loo hubiyo in qiimaha PH ee biyuhu u dhexeeyo 5-7 .

Fosfatinta

Waxa loogu yeero fosfatinta, waxaa loola jeedaa workpiece biraha ka dib markii ay ku jiraan dihydrogen fosfat acid daawaynta, falcelinta kiimikada iyo in ay dusha sare si ay u abuuraan lakabka ah ee filimka fosfateet xasilloon oo aan milmayn, filimka waxaa loo yaqaan filim fosfat.Ujeedada ugu weyn ee filimka fosfatinta waa in la kordhiyo adhesion of daahan iyo hagaajinta iska caabinta daxalka ee daahan.Waxaa jira habab badan oo fosfatinta, marka loo eego heerkulka fosfatinta, waxaa loo qaybin karaa fosfat heerkul sarreeya (90-98 ℃), fosfat heerkulka dhexdhexaad ah (60-75 ℃), heerkulka hooseeya ee fosfatinta (35-55 ℃) iyo heerkulka caadiga ah. fosfatinta.

Dareenka

Tiknoolajiyada passivation ee filimka fosfatinta ayaa si weyn looga isticmaalaa Waqooyiga Ameerika iyo wadamada Yurub.Tiknoolajiyada passivation waxay ku saleysan tahay astaamaha fosfatka laftiisa.Filimka phosphating waa dhuuban, guud ahaan 1-4G / m2, ugu badnaan kama badna 10g/m2, aagga daloolka xorta ah waa weyn yahay, iska caabinta daxalka ee filimka laftiisa ayaa xaddidan.Qaar ka mid ah xitaa in habka qalajinta on miridhku jaalaha degdega ah, ka dib markii fosfat a passivation daawaynta xiran, waxay noqon kartaa fosfat filim pore soo bandhigay oksidation biraha, ama formation of lakabka passivation, phosphating film ciyaari kara buuxinta ah, oksidation ah, ka dhigi phosphating film xasiloon ee jawi.

Qalajinta filimka fosfatka

Qalajinta filimka fosfooraska ayaa ka ciyaari kara laba door, dhinaca kale, waa in loo diyaariyo habka soo socda si looga saaro biyaha dusha sare ee filimka fosfatinta, dhinaca kale, waa in la sii wanaajiyo iska caabinta daxalka ee filimka. dahaarka ka dib.

Si loo dhiso xariiqda dahaarka ka hor, naqshadeynta habka waa in la dhammeeyaa ka hor naqshadeynta, soo saarista iyo rakibidda qalabka aan caadiga ahayn.Sidaa darteed, naqshadeynta geeddi-socodka waa aasaaska khadka wax-soo-saarka, iyo dariiqa saxda ah ee macquulka ah ayaa saameyn wanaagsan ku yeelan doona hawlgalka wax soo saarka iyo tayada alaabta.

Loo isticmaalo dhammaan noocyada rinjiyeynta workpiece, moodooyinka kale waa la beddeli karaa.